Electronics development

We create value for our customers through innovative thinking and the highest quality of electronic product development, solutions and systems. Book a meeting

The right partner for the development of your electronics

With our skills in electronics development and mechanical design, we have the ability to develop every aspect of your product. Furthermore, we also offer to provide all aspects surrounding the product development process, from the idea phase, to production and after-sales service.

With a focus on developing products that contribute to the success of our customers, we believe that we can offer the perfect partnership.

You are welcome to contact us with queries regarding the development of your product. We can arrange a meeting to discuss your product, you as a customer, as well as your technical and financial expectations. This way, we will be able to provide you with an offer that best suits your needs.

We strive to make the entire process fast, efficient and flexible, without compromising on our solutions.

At CB Svendsen we have:

- Experience in the industry since 1969

- The competencies for the development of a wide range of product types and technologies

- Knowledge of the quality, production and financial aspects behind the finished product

- Focus on national and international standards and environmental conditions

If you choose us to handle your electronics development needs, you get:

Partnership

With our know-how, skills and focus on delivering products that contribute to the success of our customers, we believe we can offer the perfect partnership.

Expertise

Our development department in total exceeds 100 years of experience and the execution is never far from the idea.

.

Production optimisation

With all processes in mind, and our know-how acquired through internal production, we always develop products that are optimised in relation to relevant production processes.

Process flow

We ensure a structured process flow, where all our specialist departments collaborate to ensure the quality of the development of your product.

Quality

We take into account all stipulations regarding your product and make sure to comply with relevant standard, approval and environmental requirements.

Documentation

Everything is documented during our development process. The documentation contains all the information necessary to produce and test the product.

Warranty

We provide up to 24 months warranty on all of our products. All documentation is stored for at least 10 years after the development process is completed.

Contact

You are assigned a permanent contact person and are given direct access to the relevant departments and professionals attached to your project.

When we develop products, we use the following tools:

Embedded software

Firmware for, among other things, large industrial machines with user interface, ethernet, modbus and USB for small consumer devices with Bluetooth LE and several years of battery life. Motor driver systems and LED driver. Cellular connectivity (GSM, GPRS, LTE, etc.), wireless protocols and battery optimisation for IoT products.

PC software

Windows and Linux applications for on-premise setup/troubleshooting of equipment, reference implementations of protocols and internal testing programs.

Test software

LabView programs for automatic programming, testing and validation of firmware and hardware during production. Also used for monitoring and ongoing statistics that provide data basis for production optimisation.

Web applications

Web systems for presenting data, managing of thousands of IoT devices, user management and the like.

Hardware

Development of electronics for, among other things, industry and consumer products. Analog and digital solutions for motor and LED driver systems, wireless technologies, interface systems, operation monitoring, battery technology and much more.

Layout

PCB layout in OrCad of prints in all sizes, any number of layers and materials,

Mechanics

Products and mechanical items are designed in SolidWorks, where the only limit is imagination. We design the exterior of the products, as well as sub-components, such as buttons, cables, reliefs, springs, screens with vandal protection. Everything that makes the product look good and function.

Functional test, EMC og climate

In our own testing facilities, we are able to test on sub-components or finished devices and constructions. All products are tested during our development and we guarantee a positive result.

During our product development, we use e.g.

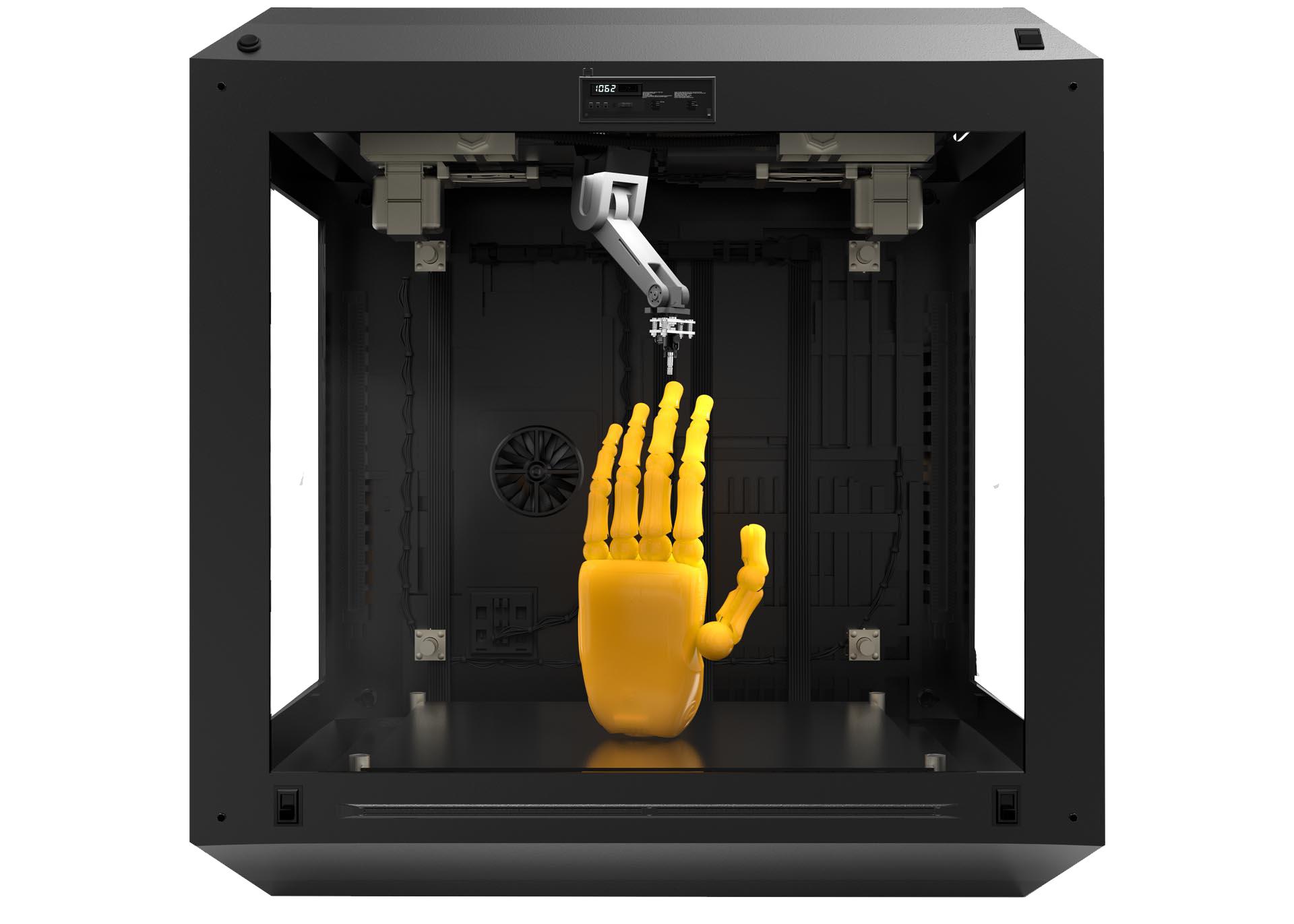

3D-printing

We use our own 3D printer and print on ABS plastic, in order to ensure the visual design, functionality and quality of the mechanical elements of your product.

The strength ratio of ABSplus thermoplastic is 70-75%, compared to molded parts. This makes them strong enough to be used in the product’s field tests and even on zero series, if necessary. We also use 3D printing in production test equipment, where possible. Not only does this optimise the cost of the equipment, it also provides design freedom and thereby the opportunity for an optimal testing process and result.

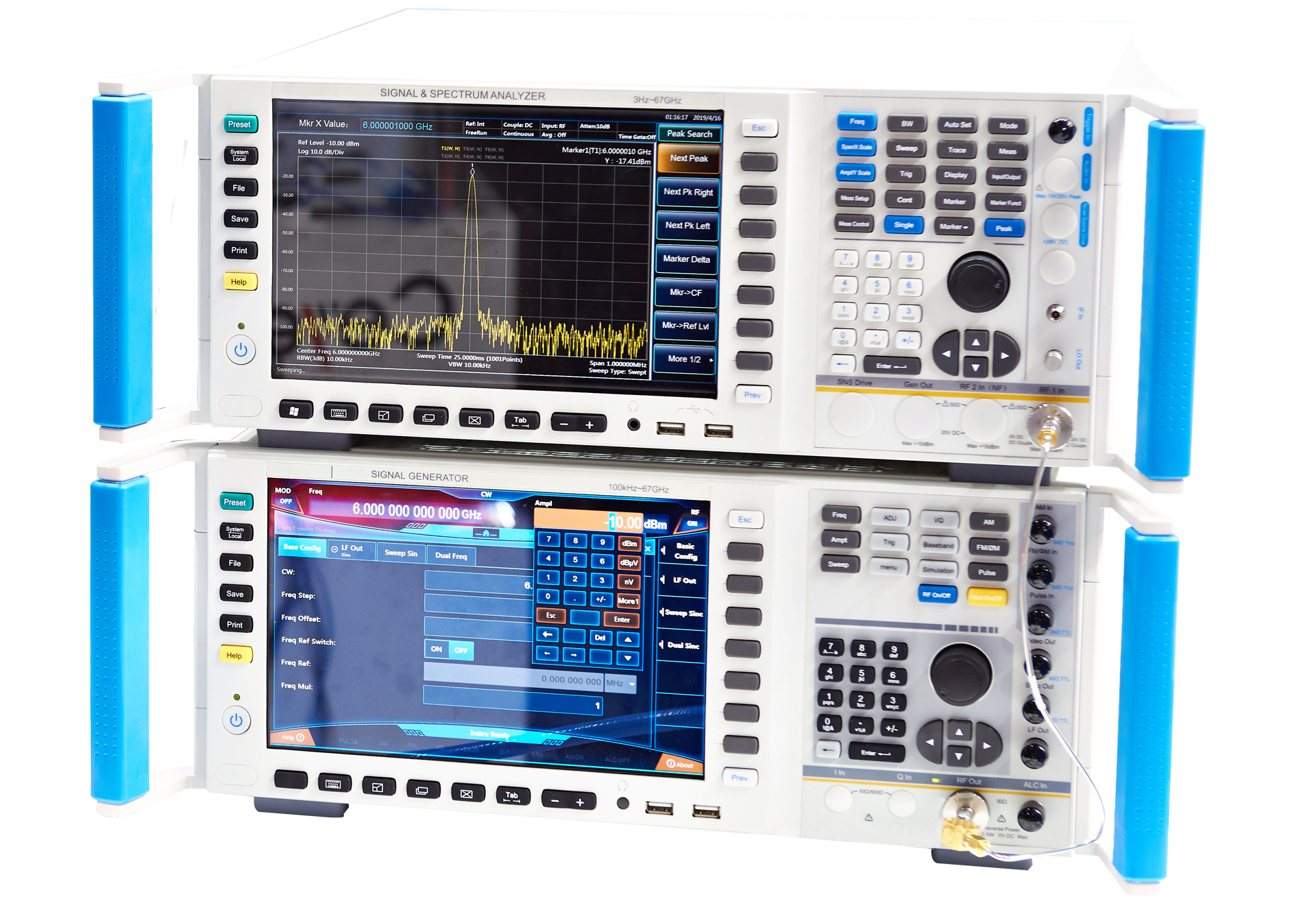

EMC measurement

We have our own internal EMC laboratory, which allows us to test the products, solutions and systems that we develop. With these elements, we are able to secure the EMC-relevant areas, such as device design, print layout and component selection. In this way, we can guarantee that our products meet national and international standards.

The EMC laboratory can be used in connection with a development process where ongoing CE tests are included in the development plan. In this way, the finished product can more easily go through the final approval process by a Notified Test Body.

Serigraphy

Our serigraphy department has expertise in various printing methods, design and production of foils and foil keyboards, stickers and labels and milled items in thin plate. This is often used in products that contain mechanical items and require a proper look and feel.