Electronics manufacturing

We create value for our customers through innovative thinking and the highest quality of electronic product manufacturing, solutions and systems. Book a meeting

Electronics manufacturing with quality in mind

Your product is made with our state-of-the-art electronics manufacturing. Our expertise in the production of complete electronics products quickly and efficiently makes your product available to the market, at competitive prices. From prototype to scalable production. We provide all facets within electronics manufacturing, from production maturation, to box build, to quality assurance and after-sales service.

With a focus on developing products that contribute to the success of our customers, we believe that we can offer the perfect partnership. We are passionate about experiencing the success of the marketing of your product.

You are welcome to contact us with queries regarding the development of your product. We can then arrange a meeting to discuss your product, you as a customer, as well as your technical and financial expectations. This way, we will be able to provide you with an offer that best suits your needs.

We strive to make the entire process fast, efficient and flexible, without compromising on our solutions.

At CB Svendsen we have:

- State-of-the-art production equipment

- Opportunity to scale production

- Quality in mind and an understanding of the financial side

- Focus on national and international standards and environmental conditions

If you choose us to handle your electronics manufacturing needs, you get:

Partnership

With our know-how, skills and focus on delivering products that create value for our customers, we believe that together we can create the perfect partnership.

Expertise

Our production department was founded in 1969 and works with most technologies within electronics assembly. We therefore have the highest level of know-how and our expertise always benefits our customers.

Production optimisation

With all processes in mind and our know-how acquired through internal development, we ensure that the product is optimised and ready for production.

Process flow

We take responsibility for the entire production process. With our documented and certified processes, we make sure to deliver a quality product on time.

Quality

We take into account all stipulations regarding your product and make sure to comply with relevant standard, approval and environmental requirements.

Flexibility

Our production is geared to create value for our customers, regardless of whether we are dealing with prototype or volume production. Through a flexible mindset, we always make sure that the needs of the customer are met.

Warranty

We provide up to 24 months warranty on all of our products. All documentation is stored for at least 10 years after the manufacturing process is completed.

Contact

We create the framework for good cooperation through constructive dialogue. You are assigned a permanent contact person and are given direct access to the relevant departments and professionals attached to your project.

We offer the following in electronics manufacturing:

Electronics assembly and device assembly

With leaded SMD and Through Hole Technology (THT), we carry out efficient electronics and device assembly, in high quality, based on our workmanship standard.

Testing

Development and construction of electronic test stands for both internal tests and directly for you as a customer.

Mechanics og electronics

Execution of “heavy” electrical and mechanical end assemblies. For example, control cabinets for landing lights at airports, large power supplies for the Norwegian Armed Forces and information boards for Arriva.

Cleaning of printed circuit boards

In a special washing machine, we clean mounted printed circuit boards, where the conductivity of the water is continuously checked.

Varnishing/embedding/gluing

We have extensive experience with varnishing and embedding printed circuit boards that are to be used in particularly demanding environments. For example in EX zones.

We also deliver:

3D-printing

We use our own 3D printer and print on ABS plastic, in order to ensure the visual design, functionality and quality of the mechanical elements of your product.

The strength ratio of ABSplus thermoplastic is 70-75%, compared to molded parts. This makes them strong enough to be used in the product’s field tests and even on zero series, if necessary. We also use 3D printing in production test equipment, where possible. Not only does this optimise the cost of the equipment, it also provides design freedom and thereby the opportunity for an optimal testing process and result.

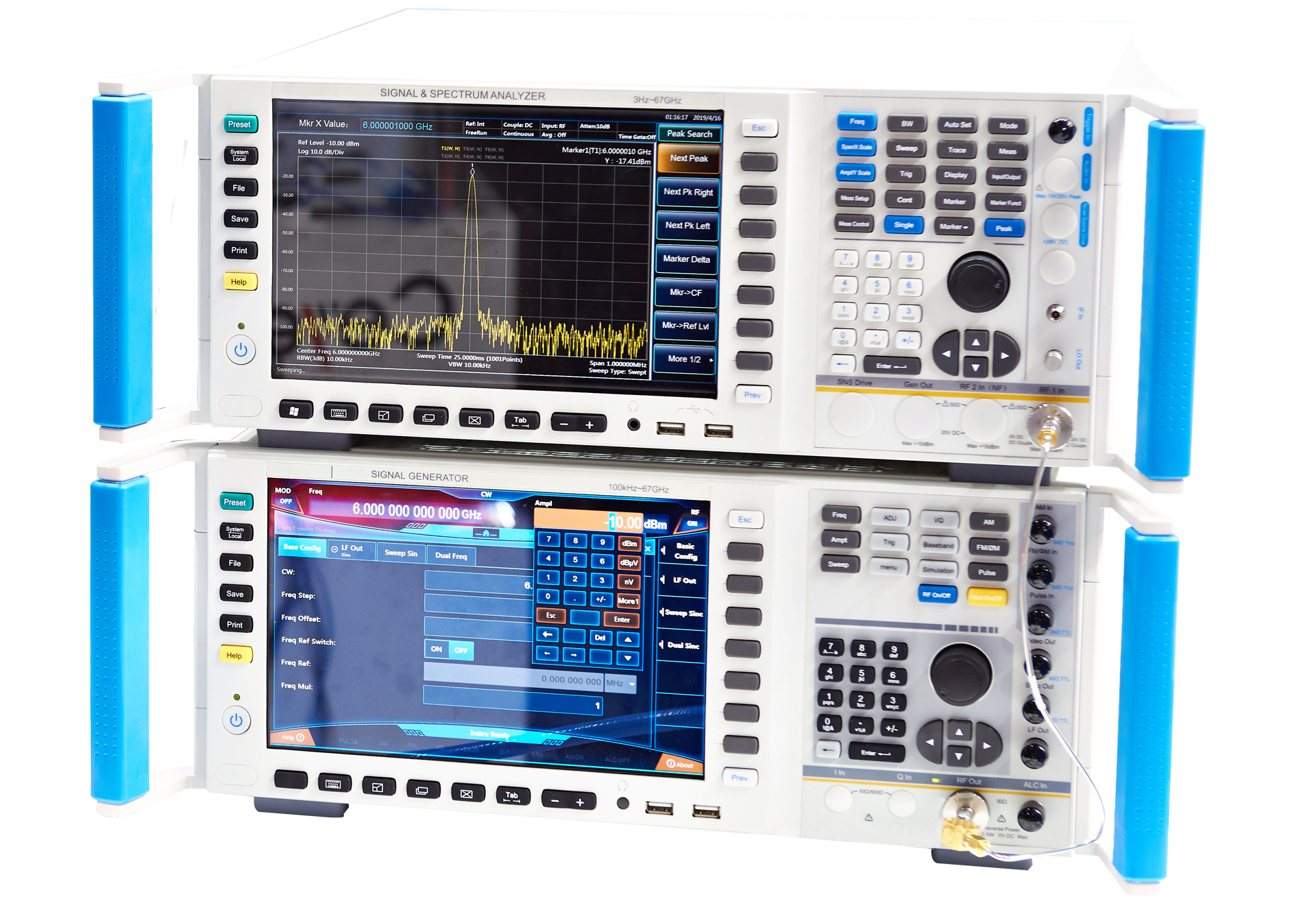

EMC measurement

We have our own internal EMC laboratory, which allows us to test the products, solutions and systems that we develop. With these elements, we are able to secure the EMC-relevant areas, such as device design, print layout and component selection. In this way, we can guarantee that our products meet national and international standards.

The EMC laboratory can be used in connection with a development process where ongoing CE tests are included in the development plan. In this way, the finished product can more easily go through the final approval process by a Notified Test Body.

Serigraphy

During the production of electronics, serigraphic printing on your electronics may become necessary. Serigraphic printing is a printing technique that makes colour prints on items in a way that can withstand all kinds of weather and touch. The serigraphic print binds to the material, is suitable for many types of materials and has a long durability. We also perform milling and drilling of plastic and metal items on CNC machines.

With our own in-house screen printing department, you will be sure to have an optimised process and complete production from A to Z.